Taichung City, TAIWAN

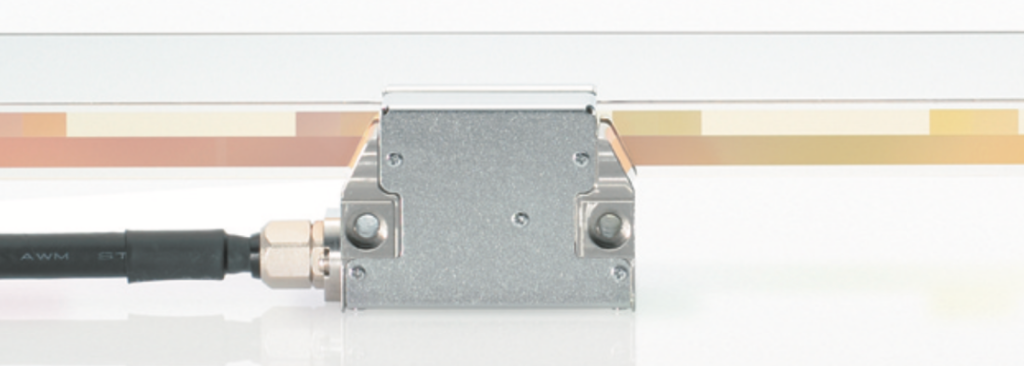

Transmissive type Laserscale®

The LS series from Magnescale pushes the boundaries of precision measurement—transcending nanometer resolution into the picometer realm. This leap in performance has advanced at a pace reminiscent of Moore’s Law, aligning with Magnescale’s strategy of anticipating and meeting future customer demands. Its exceptional resolution and stability make it indispensable in domains that demand ultimate precision, such as next-generation semiconductor manufacturing, camera-lens mold fabrication, and ultraprecision machining. Furthermore, Magnescale has extended its measurement capabilities beyond one-dimensional positioning to 2D and even 3D, integrating Z-axis sensors and creating some of the world’s most accurate angular encoders.

Magnescale’s LS systems integrate several proprietary technologies to achieve unprecedented accuracy. The grating interferometer scale maintains precision unaffected by temperature fluctuations, air pressure changes, or turbulence. Holographically generated scales produce output signals with exceptional linearity and high diffraction efficiency, ensuring minimal distortion and superior signal-to-noise performance. Additionally, advanced interpolation and signal compensation processing deliver remarkable resolution, with the BS series achieving ~17 picometer resolution using automatic compensation interpolation. LS units are widely applied in ultra-high-precision air-bearing stages, surface roughness and contour measurement systems, DUV wafer inspection systems, non-contact measuring machines, micro-grinding tools, and aspherical surface machining equipment.

The semiconductor industry is one of the most demanding fields for precision measurement, where nanometer and picometer positioning accuracy directly impacts yield, device performance, and production throughput. Magnescale’s LS technology is critical in enabling these capabilities across multiple processes:

Lithography Systems: LS provides ultra-stable, high-resolution feedback to position wafers with sub-nanometer accuracy, ensuring correct overlay of multiple circuit layers.

Wafer Inspection and Metrology: With picometer-scale resolution, LS ensures precise stage positioning for optical and electron-beam inspection tools.

Etching and Deposition Equipment: LS feedback enables real-time motion control for consistent substrate positioning during plasma etching or thin-film deposition.

Mask and Reticle Manufacturing: LS supports defect inspection, laser writing, and high-precision pattern transfer processes with resolutions as fine as 2 pm.

Packaging and Backend Processes: Compact LS systems (e.g., BH series) provide precise positioning feedback in confined spaces for advanced 2.5D and 3D IC stacking.

By combining holographic scale technology, grating interferometry, and advanced interpolation, LS overcomes environmental disturbances such as temperature drift, air turbulence, and mechanical errors. This makes it an indispensable technology for nanopositioning stages, wafer handling systems, and inspection equipment across the entire semiconductor value chain—from front-end lithography to backend packaging.

Magnescale LS technology delivers unparalleled performance that distinguishes it from conventional encoders and measurement systems. Its core advantages include:

Picometer-Level Resolution: Achieving resolutions down to ~17 pm, LS enables ultrafine positioning and measurement that meets the strictest requirements in semiconductor, optics, and ultraprecision machining industries.

Exceptional Environmental Stability: The combination of grating interferometry and holographic scale design ensures measurements remain accurate despite temperature fluctuations, air turbulence, or mechanical vibrations.

High Linearity and Signal Integrity: Holographically generated scales provide strong optical signals with minimal distortion, offering superior signal-to-noise performance for reliable feedback in high-speed and high-precision applications.

Versatile Multi-Dimensional Capability: LS supports 1D, 2D, and 3D positioning, including compact Z-axis and angular encoder integration, allowing seamless use in complex nanopositioning systems.

Advanced Interpolation & Compensation: Proprietary interpolation circuits and automatic signal compensation deliver consistent accuracy, eliminating errors caused by mechanical or environmental factors.

Overall, these advantages make Magnescale LS an essential solution for industries requiring ultimate precision, enabling reliable and repeatable measurements across a wide range of applications—from high-speed motion control and semiconductor fabrication to ultraprecision machining and metrology.