Taichung City, TAIWAN

數位探規 採用高等級的磁性記錄與偵測原理,這項技術已經發展超過 50 年。充分體現了 (Sony) Magnescale 一貫的可靠性與品質。其具有高解析度與高精度,同時具備耐環境、耐震動與抗振能力,這些都是我們磁性感測原理獨有的特性。

創新的主軸設計提供0.1um重複精度與提升的抗扭轉能力,並支援 IP67 環境防護等級,適用於廣泛的應用領域。

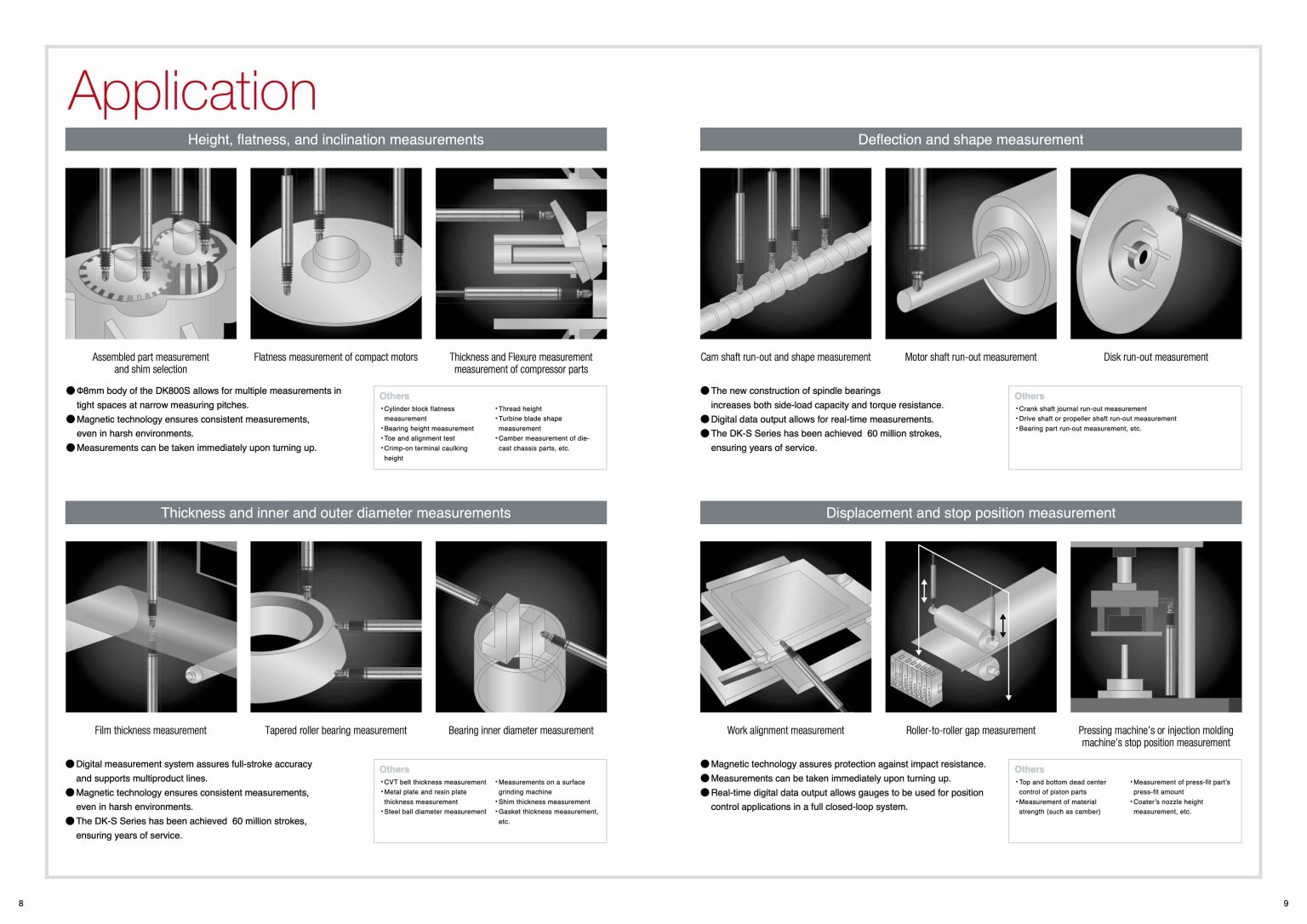

Sony Magnescale’s Digital Gauge is an advanced measurement instrument designed for high-precision applications in various industries such as manufacturing, engineering, and research. It utilizes cutting-edge technology to deliver reliable, accurate, and efficient performance in the measurement of linear displacements and positions. Known for its exceptional durability and high-resolution output, the Digital Gauge is widely used for applications where minute variations in measurements are critical.

At the heart of the Magnescale system is a magnetic encoder, which offers a contactless solution to linear measurement. The magnetic field is detected by a sensor and converted into digital signals that are then processed to produce precise positional data. This contactless operation not only enhances accuracy but also reduces wear and tear on the components, making it a highly reliable choice for long-term use. Unlike traditional optical encoders, the Magnescale Digital Gauge is resistant to contamination such as dust, oil, and moisture, making it suitable for harsh environments.

One of the standout features of the Sony Magnescale Digital Gauge is its high resolution, which can detect minute changes in position down to microns or even nanometers, depending on the model. This level of precision is critical in industries like semiconductor manufacturing, precision machining, and aerospace, where even the smallest deviation can lead to significant errors. The device’s ability to maintain accuracy over extended periods of use without requiring frequent recalibration further enhances its appeal.

The Digital Gauge is designed to be user-friendly, featuring a simple interface that allows operators to quickly interpret measurement data. It includes a clear digital display, making it easy to read results even in low-light conditions. Additionally, the gauge offers various output options, including RS-232 and USB, for seamless integration into automated systems or data logging applications.

In terms of durability, the Sony Magnescale Digital Gauge is built to withstand the rigors of industrial environments. Its robust construction ensures that it can endure mechanical stresses, vibrations, and temperature fluctuations, all while maintaining accuracy. Furthermore, the gauge’s design is often compact and lightweight, ensuring ease of installation and minimal space requirements.

Another key advantage of the Magnescale Digital Gauge is its versatility. It can be used for a wide range of applications, from simple measurement tasks to complex automated systems. Whether used for measuring the position of a moving part in a CNC machine or verifying the alignment of components in a quality control process, the gauge delivers exceptional performance in diverse settings.

In conclusion, the Sony Magnescale Digital Gauge stands out as a high-performance, versatile, and reliable solution for precise linear measurements. With its advanced magnetic encoding technology, resistance to contamination, and ease of use, it continues to be a valuable tool in a variety of demanding industrial and scientific applications.